Hi All,

This is my first post on here, I’ve got a far amount of experience with industrial robots but this is my first experience of a UR10e, I have two of them infact, performing a slightly complex pick and assemble task.

The task itself is relatively simple aside from I have 18 pick positions and 4 place positions, I have sorted the logic for that but I have found another issue.

The part I am assembling only has around a 2mm tolerance to fit into the other part. This is proving tricky as sometimes theres a small misalignment on pickup and the part its assembling to must have a small gap for running down a conveyor so niether are perfect.

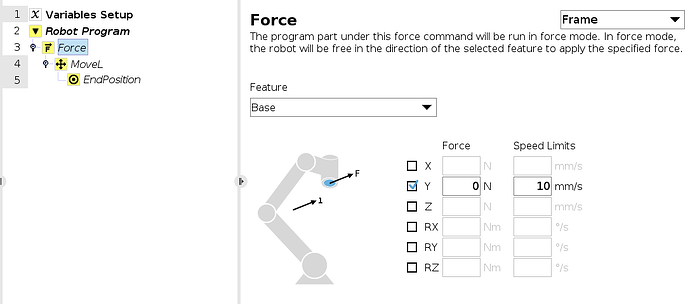

Now I am using a force measure to get the part down into the assembly, this works but every now and again there is a misalignment in feature base direction Y, this can be Y-, Y+ generally only 1-2mm.

This can cause the robot to crash out, the issue is I cannot make the the clip pickup any tighter, nor the conveyor any tighter.

Previously on industrial robots I have seen the force vector used to offset the robot position. So in effect if the robot sees a Y+ force of greater than “5” or whatever then it moves in the opposite direction by a fixed value, or until that force becomes less than “5” and vice versa for Y-.

Is there anyway to do that on the ur10e?

I am using get_tcp_force and monitoring the Z value for my placement, so I was thinking I could run an event when the robot is in this Z movement to montior the Y value, but I am not sure how I could get the logic to drive in Z then stop adjust by a fixed value then drive in Z again until the Z force is greater than my other preset variable.

Any help would be appreicated.

Thanks

Scott