Hello everyone,

I’m currently working on a project involving a Universal Robots (UR) arm in a manufacturing setup where the parts produced by our CNC machine vary in dimensions between batches. The challenge we face is that every time we receive a new batch with a different dimension, we need to rescript the UR arm to properly grip the finished product. This process is time-consuming and reduces our efficiency.

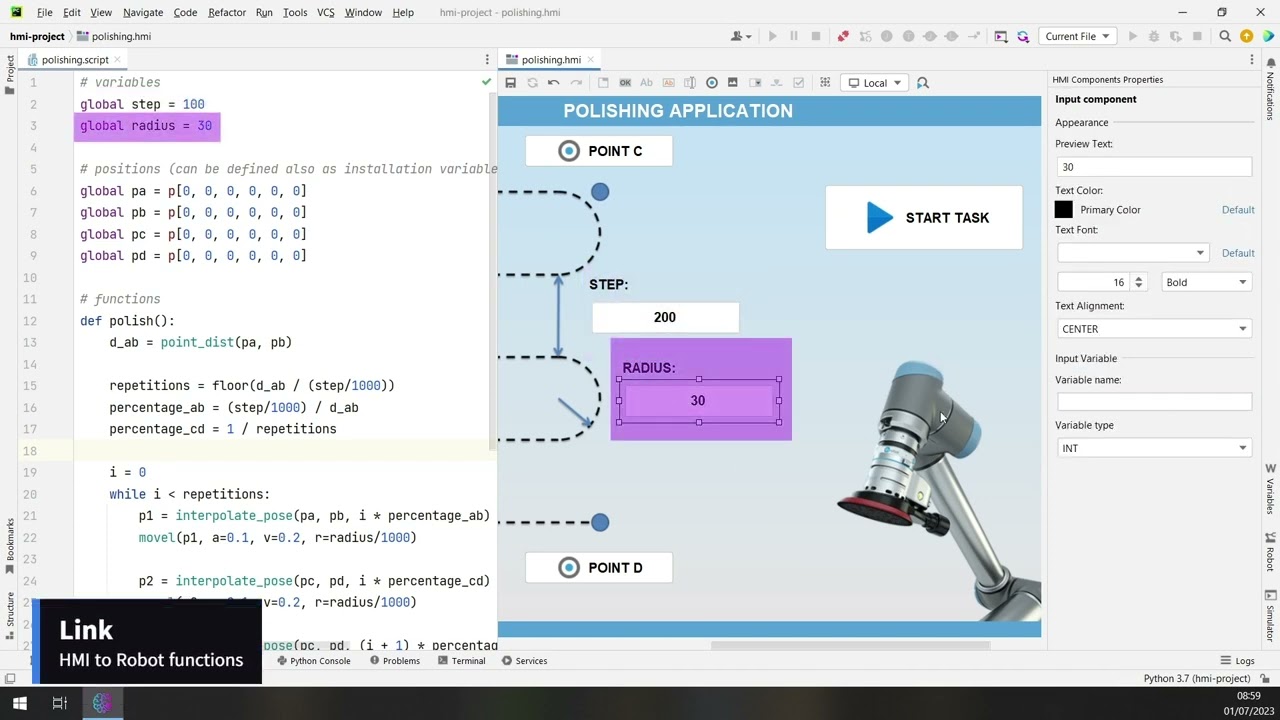

I want to automate the process so that the UR arm can adapt to different part dimensions (diameter and depth) without needing to rescript every time. The idea is to input the dimensions of the parts for each batch, and have the robot adjust its gripper automatically to handle the parts correctly.

I’m new to using UR’s products and would be open to any questions or suggestions!

I am using the UR10e with the 3FG15 3-prong electric gripper